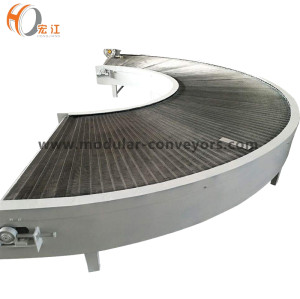

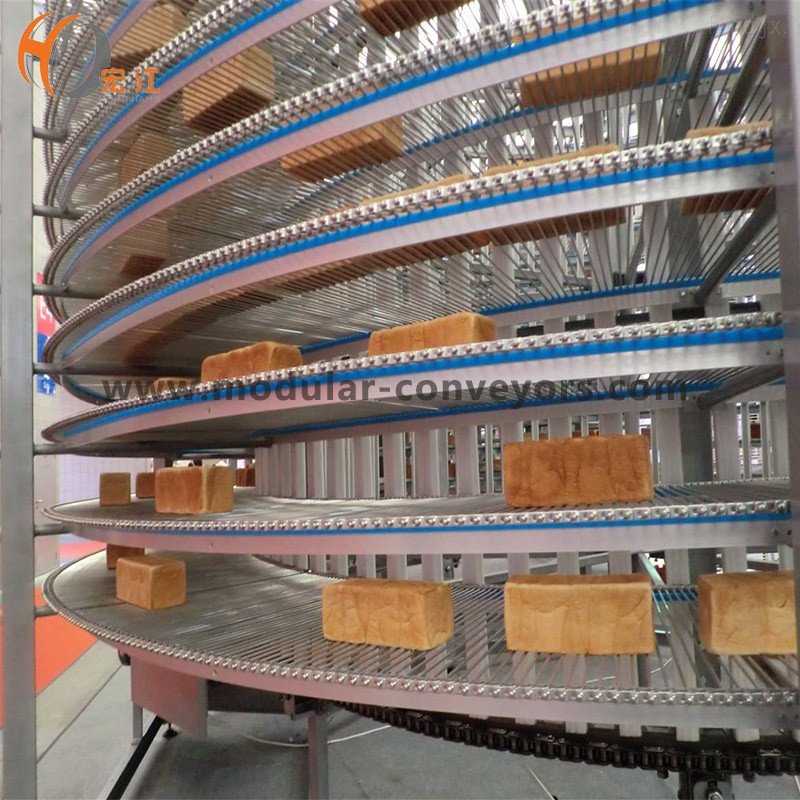

Bread spiral cooling tower U-shaped chain spiral conveyor

Item specifics

- Material

- S.S304 or S.S316

- Certification

- CE, SGS, ISO

- Warranty

- 1 year

- MOQ

- 1 set

- Package

- Packed by wooden case

- After-sales service

- Engineer is avialabe for overseas service

Review

Description

Bread spiral cooling tower U-shaped chain spiral conveyor

The spiral mesh chain is a stainless steel mesh belt composed of a mesh, a shaft, a U-chain and a stainless steel cap.

Different from ordinary metal mesh belts, the spiral mesh chain is made of high-quality food grade bright SUS304 spring stainless steel. The mesh surface is flat, the chain and the shaft are connected flexibly, and the general chain has protective high ribs. The end of the net rod adopts a beaded or nut type structure. The characteristics of the net chain are that there are many welding processes, and the welding of the spiral mesh belt has certain difficulty. It is necessary to weld the stainless steel straight strip, the U-shaped chain and the small cap with one welding spot, and the current needs to be adjusted to a large degree during welding. The place must be strong and tidy and look good.

Spiral net chain features:

1. Use sprocket drive for accurate and stable operation.

2. The net chain on the same production line can go straight, or you can change the walking.

3 Its strong elongation resistance, high wear resistance and long service life

4. Use automatic machine welding to ensure that the edges are equal and smooth.

5. The whole process is electrolytic pickling, and the mesh belt is degreased as a whole.

6, the net surface is bright and clean, in line with food-grade standards

7, large carrying capacity

8, the use of small space

The spiral mesh chain series is suitable for smaller spiral radius conveyor lines. Scope of application: conditioning of food, ice cream, pastry, split meat, aquatic products, fried foods, small packaged foods, frozen, moon cakes, bread, burgers, various cakes and other products.

Order the data required for the spiral belt:

1: Provide spiral tower rotation radius: radius of rotation = 1.7 x net width, radius of rotation = 2.2 x net width, radius of rotation = 1.1 x net width.

2: Select the chain pitch according to the spiral tower rotation size: (pitch: 19.05mm, 25.4mm, 27.25mm, 27.4mm, 30mm, 31.75mm

Add mesh or no mesh).

3: According to the transportation product selection materials: 304 and 316 stainless steel.

The specific function of the spiral tower is introduced:

Cooling

Cooling a variety of baked goods, fried foods, cooling methods can be divided into two types of natural cooling and forced cooling.

2. proofing

We supply a precise humidification and heating system with circulating air to ferment the food dough such as bread buns on the surface of the spiral conveyor belt, and generally connect the supporting production line at the front and rear interfaces of the spiral tower for users. The production efficiency is greatly improved, the space is saved, and the entire wake-up process is realized by the monitoring system to realize unmanned automatic production.

3. Quick freezing

Deep-frozen spiral towers can be made for quick-frozen food applications, and spiral frozen towers are suitable for bulk and packaged foods. At minus 40 ° C

Operate as usual at temperature. Provides quick-frozen solutions for bread, pizza, tarts, baked frozen foods, dumplings, stews and fresh vegetables and fish meats.

Product Picture

Application

If you need any help for conveyor design and manufacture, pls feel free to contact me:

WhatsApp : +86 15013068448

Skype: Karri Yao

Mobile: +86 15013068448

Email:karri@plastic-conveyor.com