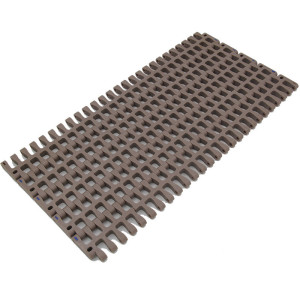

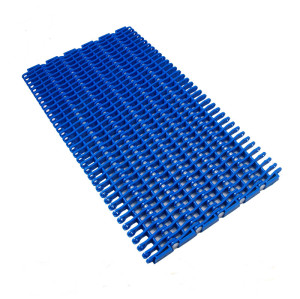

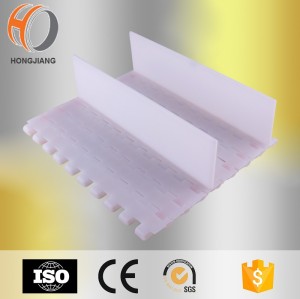

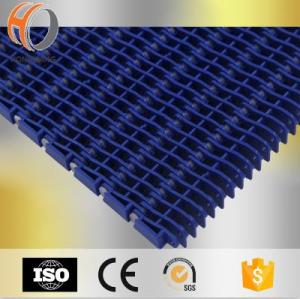

Plastic Flat Top food grade PP Material OPB 9705 modular Belt

- Model

- H9705

Item specifics

- material

- pp

- pitch

- 50.8mm

- color

- white

- certification

- ISO9001:2008

- structure

- belt conveyor

- brand name

- hongjiang

- place or origin

- guangzhou

Review

Description

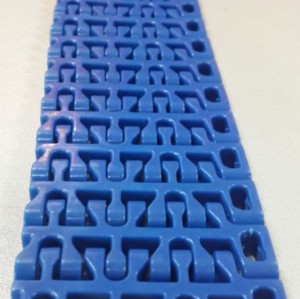

Plastic modular belts offer many advantages over conventional flat belt system. These plastic modular belts offer rugged yet flexible design features which are increasingly used for food processing and conveying besides several engineering applications. As the name suggests, the belts are made up of plastic modules arranged in staggered (brick wall) pattern and assembled on full-length polymer hinge rods, which gives inherent strength to the belt. The modules are held in place on the rods by end-locks. Our range consists of straight line belts and side flex belts.

Belt Type | Material | Working Load(max) | Weight | Temperature | Backflex Radius(min) | ||

N/m(21°C) | lb/ft(21°C) | Kg/square meter | dry | wet | mm | ||

OPB-FG | POM | 22000 | 1507 | 11.7 | +4 to +80°C | +4 to 64°C | 75 |

PP | 11000 | 754 | 7.5 | +5 to +104°C | +5 to +104°C | ||

The main advantages which these belts offer are:

- Simple modular construction

- Different top surfaces for various applications

- Washable, physiologically safe and chemical resistant

- Low maintenance, easy to clean and repair

- Positively engaged sprocket drive eliminates slippage and tracking problems

- Square bore sprockets provide better torque transmission efficiency

- Smooth and quiet running

- Lightweight and energy efficient

- Flights and buckets are available for inclined conveying

- Available for sub-zero as well as high temperature applications