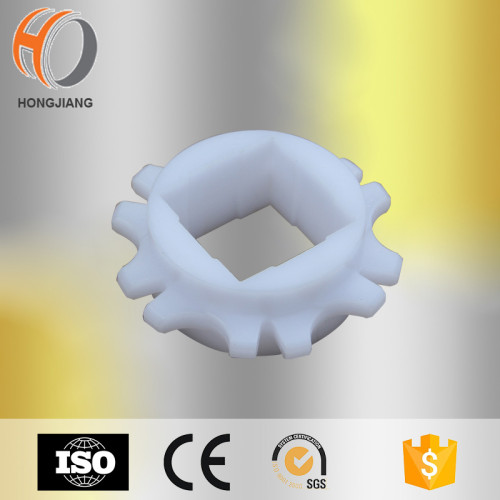

Thermoplastic injection mould sprocket use for H900 conveyor chain

- Model

- H900

Item specifics

- material

- strong engineering nylon

- name

- injection molded sprocket

- number of teeth

- 6 , 9 , 12 , 15 , 18

- size of circle (square) bore

- 25mm, 30mm, 35mm, 40mm

- outside diameter

- 54mm, 80mm, 109mm, 131mm, 160mm

- color

- white

Review

Description

Thermoplastic injection mould sprocket use for H900 conveyor chain

Advantages:

1.Easy assembly

2.Quiet running

3.Strong engineering Nylon

4.Corrosion resistant

Description:

All sprockets have a tooth design to ensure smooth operation and chain sprocket interaction.

Sprockets made of reinforced plastic resin with glass fiber allow high torque resistance ,ensuring a very accurate tooth profile and wear resistance.

The use of plastic materials ,considerably reduces the amount of noise.

Plastic sprockets are lighter (up to 5 times )than steel sprockets and their resistance to corrosion and chemical attack is excellent .

Spilt sprocket design allows for easy assembly and disassembly of idler shafts without their removal ,reducing the time required for installation and maintainence .

No additional cost for optional guide rings .

All connecting bolts are manufactured in Stainless Steel.