What are the anti-static methods for safe use of metal mesh belt conveyors?

- Share

- Issue Time

- Mar 16,2019

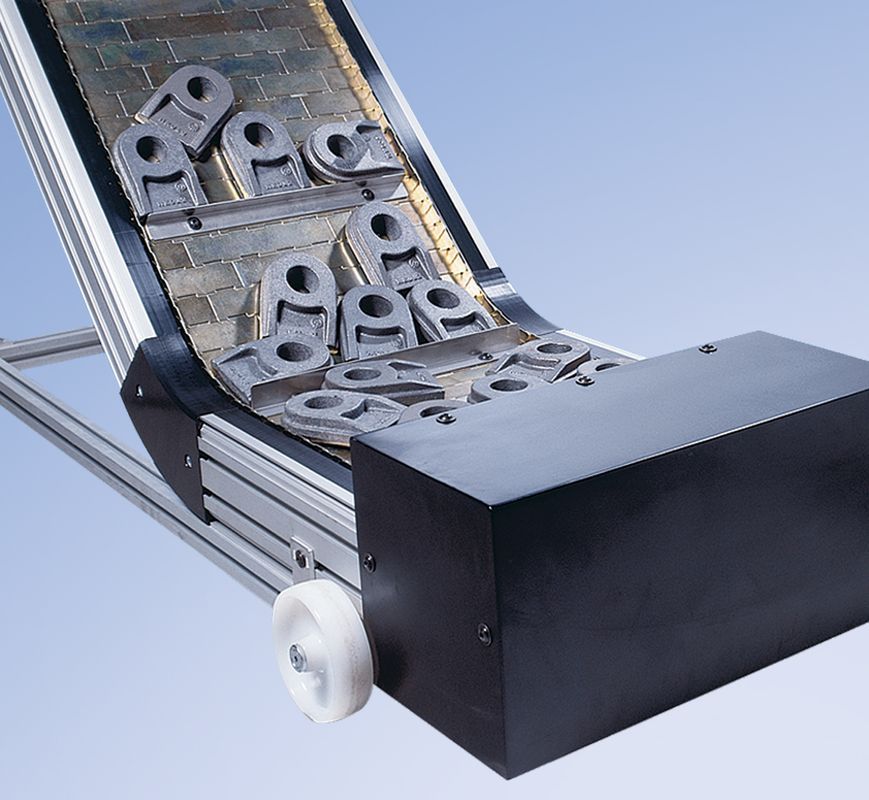

In the metal mesh belt conveyor grounding electrostatic hazard prevention method, grounding is an effective and economical method. During the process, static electricity is generated by friction, induction, or conduction. If the charge accumulates on a metal device, a conductive product, or a person's body that is insulated from the ground, the accumulated charge will release the energy in one discharge. Such electrostatic discharges are the main cause of electrostatic hazards. The metal mesh belt conveyor control method is to ground all the objects and maintain a low grounding resistance, and the electric charge accumulated on the metal equipment, the conductive products or the human body is quickly dissipated to the earth to avoid metal mesh belt transportation. Machine electrostatic hazard accident.

Precautions for the safe use of metal mesh belt conveyors:

1. The metal mesh belt conveyor equipment should be started at no load. After the operation is normal, it can be loaded, and it is forbidden to start after loading.

2. After the metal mesh belt conveyor is turned on, it will be idle for 3~5min. Check whether the parts are normal. The net has no slack and slippage. If there is any adjustment, the M20 tightening bolts at both ends of the driven roller can be adjusted and locked. ;

3. The metal mesh belt conveyor strictly controls the conveying capacity of the equipment, prohibiting the use of overload, and causing premature failure of components;

4. The metal mesh belt conveyor checks whether the driving roller, the driven roller, the bearing housing, and the transmission sprocket (gear) have abnormal noise. If the tightness of the chain is slack, adjust the adjusting bolt of the motor board to measure the tension and tighten it. Add grease to the bearing housing and the chain once a week, and tighten the sprocket stop screw to prevent the sprocket from moving;

5. The metal mesh belt conveyor regularly inspects the mesh belt bracket, the idler roller, the motor, the bearing seat and the connecting bolts of various parts, and finds that the looseness is timely tightened.