Do you know how to install the vertical screw conveyor base motor?

- Share

- Issue Time

- Dec 20,2018

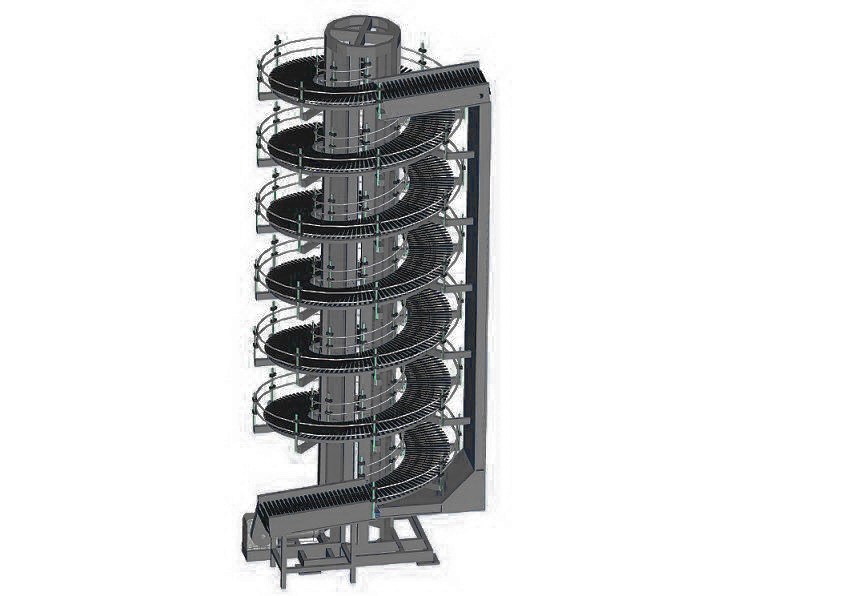

The vertical screw conveyor pushes the discharge end of the material to the upper part through the exciting force generated by the tank body. There are two basic movement modes of the material in the tank body: sliding motion and jumping motion. The material is subjected to three forces in the trough: horizontal thrust, upward thrust, and exciting forces that cause the material to jump or slide. To properly adjust the kinematics and kinetic parameters of the vertical screw conveyor amplitude, frequency, installation inclination, direction, etc., the material in the tank can be lifted or transported in the above manner. Since the two excitation motors have the same specifications and characteristics, and have a common rigid base, they can be self-synchronized without other mechanical connections, and can be produced in the same way as parallel-axis inertial exciters. The inertial excitation force in the vertical direction and the torsion around the vertical axis in the horizontal plane. The two kinds of synthesis are along the oblique direction, the angle between the direction and the horizontal plane, and the angle between the direction and the bottom of the spiral groove need to be calculated according to the material specific gravity, lifting height, lifting amount and the like. The exciting force generated by the motor allows the material to be transported up the spiral groove, and the vertical screw conveyor can also transport the material downward according to the user's requirements.

The vertical screw conveyor adopts the motor as the excitation source, and has the advantages of small volume, light weight and low power consumption compared with other lifting devices. The vertical screw conveyor is a motor excitation source. It can be widely used in electric power, mining, metallurgy, building materials, chemical, fertilizer, medicine, transportation, water conservancy, railway and other industries. It is a kind of vertical spiral that can be widely used and used. Conveying machinery. This chapter mainly refers to the installation position and angle of the vertical screw conveyor base motor.

The vertical screw conveyor is mounted on the base by two cross-mounted inertia or motor as the torsional vibration source. It can also be designed as a hanging type according to user requirements, and the motor is hung on the lower part of the body. Two adjustable eccentric blocks are respectively installed on the two shaft ends of the motor; the spiral groove system is spirally wound around the central hollow cylinder of the tower body, the bottom is connected to the base, and the hook is attached, and the whole machine is supported on the four vibration isolation springs. Therefore, the vertical screw conveyor structure is very simple, mainly consists of the following parts: motor, conveyor, and base.

Vertical screw conveyors typically use the same frequency and amplitude as the parallel shaft, with an amplitude of 3-6 mm. The two screws of the vertical screw conveyor are installed in a cross mode, that is, two motors are respectively placed on both sides of the hoist, and the two motors have a certain angle. The angle is determined according to the material to be conveyed and the height of the lift. When the vertical hoist is raised in height and the production volume is constant, the center distance of the two motors and the width of the chute should not be too large.

The two motors are cross-mounted under the tray, and the two motors can realize synchronous operation, and can generate the exciting force in the direction of the vertical motor axis and the twisting around the vertical axis of the spiral body. The combination of the two is a combination. The material can be transported up the spiral tank. Because of its simple structure, the vertical screw conveyor only needs to adjust the angle of the eccentric block of the motor to meet the user's needs when lifting the material, so the operation is relatively simple.