What the reasons of stainless steel chain plate cracking?

- Share

- Issue Time

- Dec 8,2018

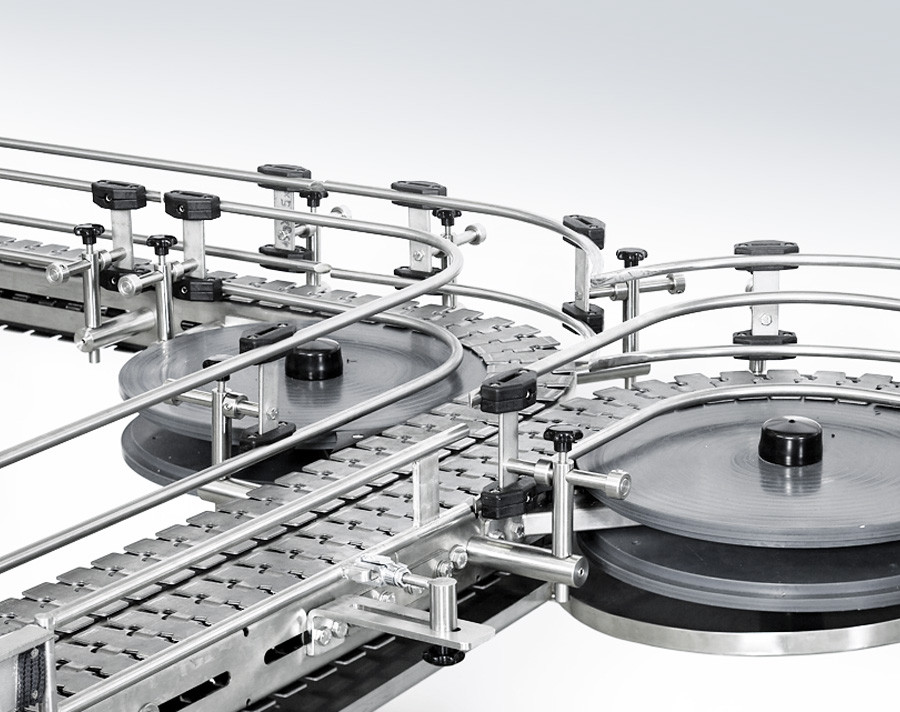

The cracking property of the stainless steel chain plate is intergranular corrosion cracking, which causes cracking under the action of cold working residual stress and tensile stress during use. Intergranular corrosion is a corrosion form in which corrosion is confined near the grain boundary and the grain itself is less corroded. As a result, the grain is peeled off or the strength of the material is lowered. The mechanism of intergranular corrosion is the theory of chromium deficiency. Stainless steel chain plate stainless steel has high corrosion resistance due to chromium content, and its chromium content must exceed 12%, otherwise its corrosion resistance is similar to ordinary carbon steel. The high microhardness test results indicate that the stainless steel solid solution effect of the stainless steel chain plate is not ideal. Metallographic examination found a large amount of undissolved carbides and distributed along the intercrystalline network, indicating that the material was not solution treated, or the solution treatment temperature was not high, the time was short, the carbides were not fully dissolved, and the degree of alloying was Poor. Moreover, the heat treatment temperature is low, the chromium diffusion rate is slowed down, the chromium carbide precipitation is accelerated, and the formation of the chromium-depleted region is accelerated. Meanwhile, the chromium carbide distributed along the grain boundary exacerbates the grain boundary chromium deficiency, if the chromium content falls to 12% ( Below the limit chromium content required for passivation, the chromium-depleted zone is in an activated state, and as an anode, it forms a corroded galvanic cell with the die. The chromium-depleted zone is an anode with a small area, the crystal grain is a cathode, and has a large area, which causes severe corrosion of the chromium-depleted zone near the grain boundary.

For stainless steel materials, intergranular corrosion is typically produced in high temperature organic acid media. The working environment of the failed stainless steel chain plate is closely related to the pollution degree of various vehicles and the type of pollutants, and the most used in cleaning is water, so the chain plate must be in contact with the organic acid medium.

In addition, the high hardness of the stainless steel conveyor chain plate and the high carbon content of the 304 stainless steel itself will reduce the corrosion resistance of the stainless steel chain plate, and the S.S chain plate is affected by the friction between the sprocket and the transmission during operation. Stretching will increase the temperature of the stainless steel chain plate, which will also accelerate the corrosion rate of the stainless steel chain plate. Once the interlamella corrosion occurs in the chain plate, its strength is significantly reduced, so that cracking occurs under tensile stress and its own cold working residual stress. It is recommended that the manufacturer change the stainless steel chain plate material to 304 stainless steel with a lower carbon content and ensure the quality of the solution treatment of the raw materials. After this measure, the produced stainless steel chain has not cracked in use.