A few tips on adjusting the belt conveyor belt deviation

- Share

- Issue Time

- Dec 6,2018

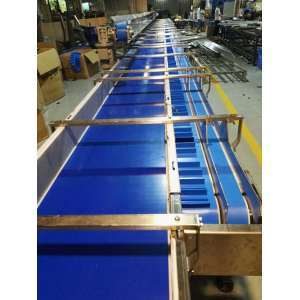

The belt conveyor has been widely used in agitation, crushing and screening equipment. During the operation of the conveyor, the belt deviation phenomenon often occurs due to various reasons, which will not only cause leakage, abnormal wear of the equipment and Damage, reduced productivity, and can affect the normal operation of the entire equipment. Therefore, it is a very important task to correctly determine the cause of tape deviation and eliminate it in time.

The fundamental reason for the deviation of the conveyor belt is that the combined force of the external force of the belt in the belt width direction is not zero or the tensile stress is perpendicular to the belt width direction. Due to the many factors that lead to the deviation of the belt, it is necessary to solve the deviation law of the belt from the aspects of design, manufacture, installation, commissioning, use and maintenance of the conveyor: “Run tight and not run loose”, “Run high and not run low” ", "Do not run before running." That is, if the tightness on both sides of the belt is different. Then the belt moves to the tight side; if the height of the belt is different, the belt moves to the high side; if the roller bracket and the like are not installed on the vertical section of the belt running direction, but the end is in front, One end is behind (in the direction of belt travel) and the belt moves to the rear. How to adjust the conveyor belt deviation?

1. Adjust the belt conveyor tensioning mechanism. When the belt is running, if it is biased to the same side under both no-load and heavy-load conditions, the tightness on both sides of the belt is different, and should be based on “running tight and not running loose”. The rule of the screw or the weight of the tensioning mechanism is adjusted; if the belt runs away from the left and there is no fixed direction, the belt is slack and the tensioning mechanism should be adjusted.

2. Adjust the belt conveyor drum method If the belt runs off the drum, it indicates that the drum is under-level, the drum is tilted axially, or one end of the drum is at the front end. At this time, the level and parallelism of the drum should be corrected.

3. Adjust the belt conveyor roller bracket (or frame) method. If the belt always runs to one side when it is empty, the roller bracket on the side of the deviation should be moved forward by 1-2cm in the belt running direction, or The other side roller bracket (or frame) is raised appropriately.

4. Removal of the sticking method If the belt conveyor roller and the roller are partially adhered to the material, the diameter of the belt will be increased, resulting in an increase in the belt tension at the place, thereby causing a deviation. The adhered material should be cleaned in time.

5. Adjust the gravity method. If the belt conveyor belt does not run off when it is empty, it will always go to one side when it is heavy, indicating that the belt has been eccentric. The position of the hopper or belt conveyor should be adjusted so that the tape is loaded to prevent it from running off.

6. Adjusting the belt method If the belt conveyor belt edge wear is severe or the belt seam is not parallel, the tension on both sides of the belt will be inconsistent. The belt should be reconditioned or replaced.

7. Installation of the offset roller method If two sets of automatic self-aligning rollers (flat rollers or grooved rollers) are installed on the belt conveyor, the deviation of the belt can be automatically corrected. For example, when the belt runs away from the friction of one side of the small stop roller, the bracket on the side should be moved forward in the running direction of the belt, and the other side will move backwards relatively, and the belt will move backwards. Move the roller side until it returns to the normal position.

8.Installing the limit roller method If the belt conveyor belt always shifts to one side, the limit vertical roller can be installed on the frame on the deviation side; thus, on the one hand, the belt can be forcedly reset, on the other hand The roller reduces the tension of the belt on the offset side and moves the tape to the other side.

9. Install an automatic correcting device Install an automatic correcting device on the belt conveyor to prevent the belt from running off.