Do you know about automated assembly line installation and commissioning?

- Share

- Issue Time

- Nov 6,2018

The automated assembly line is a typical mechatronics device in a broad sense. It involves teaching and internships in related fields such as electromechanical automation and mechatronics. The structure used in the automated assembly line is the profile structure. The installation process of the automated assembly line is divided into: multi-station assembly, well feeding, cutting processing, pneumatic mechanical manual handling workstation, corresponding power module, PLC template, button template and industrial special sensor detection unit. The communication technology used in the automated assembly line system is the PLC industrial network communication technology, through which the linkage of the system can be realized. The process of inspection, feeding, assembly, handling, sorting and transportation in the industrial automation assembly is reproduced objectively and objectively. The automated assembly line is close to the industrial manufacturing site, and on this basis, the teaching and training are specifically designed scientifically. This can strengthen the installation and commissioning of the automated assembly line, better meet the needs of industrial manufacturing, and can better meet the on-site conditions of mechatronics and automation students' internship training.

Through this kind of simulation learning, the team ability and installation and debugging ability of the staff can be exercised, and the work ability and safety awareness of the staff can be improved. The simulation learning of the automated assembly line can also meet the requirements of the core skills training of the automation technology professional. Highlight the comprehensive application of technology.

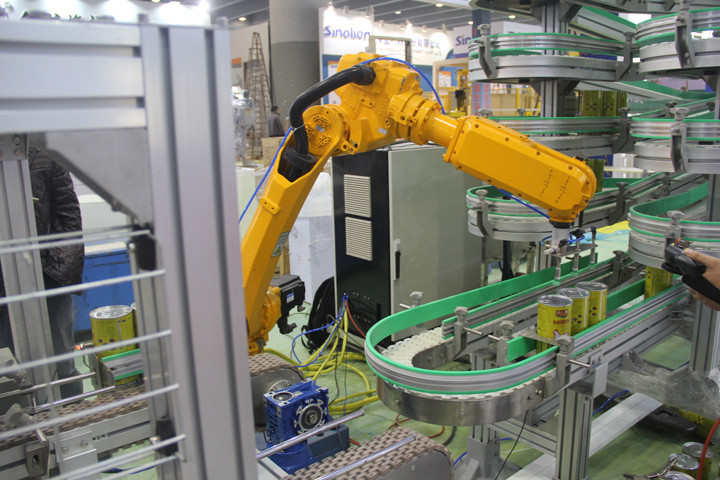

The installation and commissioning of the automated assembly line is more suitable than the requirements of the industrial city. It is a relatively common automated assembly line. From the actual industrial site, it fully considers the requirements of industrial design and aesthetics, and integrates many technologies such as mechanical, pneumatic, electrical, and sensing equipment.

The overall structure of the automated assembly line is disassembled and open, and it has a relatively obvious disassembly and assembly training function. It can be disassembled to every part and small screws, which makes it a good job to train the hands of the staff and interns, so that they can adapt to work faster. The automated assembly line has a relatively strong reorganization capability and can be assembled and assembled with different modules according to different industrial requirements.

The components and functions of the automated assembly line:

The whole of the automated assembly line consists of thirteen parts. It is divided into a material station, a processing station and an assembly station. In addition, there are handling stations, finished product sorting stations, inverter modules, power modules, PLC modules, as well as button modules and motor driver modules, as well as various sensors, and finally It is equipped with a solenoid valve, an interface for import and export, and the like. Through these parts, the automated assembly line can perform both the loading and processing of the production, as well as the sorting, assembly and transportation processes.

1, the composition of the handling station and specific functions

The main function of the handling station is to carry various accessories that need to be processed. The components of the handling station generally include stepper motor drives, mechanical components, linear guides, positioning and forming switches, including brackets and four-degree-of-freedom handling robots.

2, the composition of the material station and specific functions

The main role of the material station is to provide raw materials for the production activities of the automated assembly line. It is generally composed of a well type workpiece library, a material table, a push cylinder, and a solenoid valve, a photoelectric sensor and a bracket, and various mechanical components.