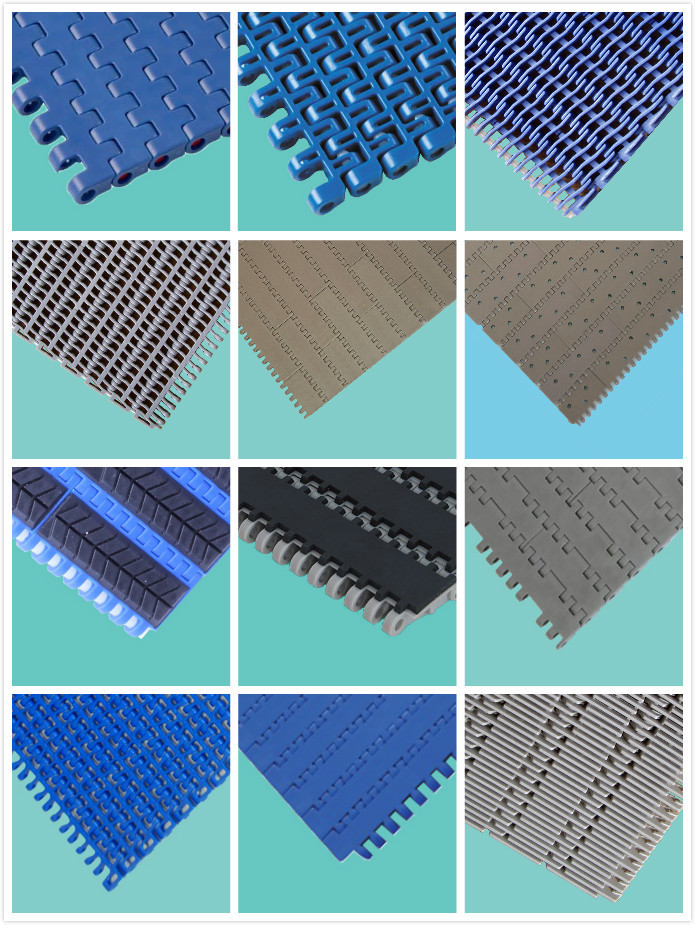

Quick freezing machine mesh belt

- Share

- Issue Time

- Oct 29,2018

Guangzhou Hongjiang Automation Equipment Co., Ltd. specializes in producing quick-freezing machine mesh belts, plastic mesh belts, plastic mesh chains, modular mesh belts. The tunnel quick-freezing machine is a high-efficiency quick-freezing device with a relatively simple structure. The impact tunnel network belt quick-freezing machine is to place the product to be frozen on the conveyor belt. The quick-freezer is driven by a plurality of high-pressure air duct fans through special customized nozzles to the wind to the upper and lower surfaces of the product. The blowing method allows for a sufficient evaporation area to better achieve the heat dissipation effect, so that the product can achieve a fast freezing effect. It is mainly used for rapid freezing of granular and blocky foods such as fruits, seafood and meat. Vertical high-speed airflow dramatically reduces freeze time. Stable product quality, reduce the dry consumption of frozen products, and improve efficiency. The structure is simple, easy to clean, and the sanitary conditions meet the requirements of the food industry. The small footprint reduces the installation space of the freezer compared to conventional quick-freezers. The taste quality of the frozen product is highly maintained.

According to different conveyor belts, it can be divided into tunnel net belt quick freezing machine and tunnel plate fast freezing machine. The mesh belt quick-freezing machine is mainly suitable for quick-frozen processing of seafood, poultry, vegetables, fruits, pasta, dairy products and the like.

Structural features:

1. Simple structure, convenient operation and long service life.

2. Made of imported equipment and modular plastic mesh belt, the surface is flat, and the width of the mesh belt can be selected according to requirements.

3. The use of thermal fluctuation blowing method, high freezing efficiency.

4. Optional single and double mesh belt combinations are available according to production requirements.

5. Use water cream to ensure cleanliness.

6. Imported frequency converter realizes stepless speed regulation, frozen product freezing time can be continuously adjusted according to needs, and can adapt to processing of various frozen products.

7. The library body is made of rigid polyurethane foam, which has good thermal insulation performance. The inner and outer brackets are stainless steel, easy to clean and meet the HACCP requirements of food hygiene.