The Functional features of automatic lifting machinery

- Share

- Issue Time

- Sep 18,2018

Lifting and transporting machinery, also called lifting equipment, elevators, hoists or elevators, is a kind of machinery that is vertically reciprocating and transporting. It is also a combination of horizontal conveyor and vertical conveyor. It is a relatively advanced and efficient automation equipment.

Features of automatic lifting machinery:

1. Automated operation and configuration of a variety of safety devices to ensure the safety of the goods;

2. The lifting car can be used together with the conveying equipment of the entrance and exit, so that the conveying process is completely automated, and the operator does not need to enter the lifting device, which can ensure the personal safety of the operator;

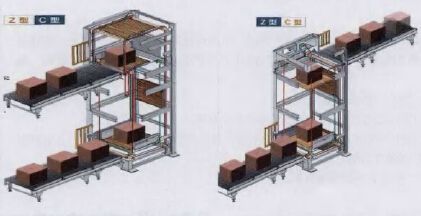

3. According to the direction of import and export, it can be divided into: Z type, C type, E type. The material can enter and exit the lifting equipment from all directions to facilitate the layout of the production workshop equipment;

4. Vertical transportation of materials adapted to large loads, the load can reach 2000kg;

5. It can realize the transportation of goods between multiple floors to improve production efficiency;

6. The equipment is controlled by PLC program. The main drive adopts German SEW reducer brake motor, and is equipped with special elevator frequency converter and special elevator guide rail to ensure the stability of the cargo during the up and down operation;

7. Lifting machinery can be divided into continuous and intermittent (reciprocating)

8. Performance parameters:

(1), maximum load: <2000Kg

(2), material type: packing box, tray, pallet

9. Can be planned, designed and manufactured according to customer requirements.

Automated lifting machinery is widely used in mass production of home appliance manufacturing, lighting, food, beverage, tobacco, postal, chemical, mechanical and electronic, warehousing and logistics.