what is the feature of metal mesh belt conveyor

- Share

- Issue Time

- Jun 26,2018

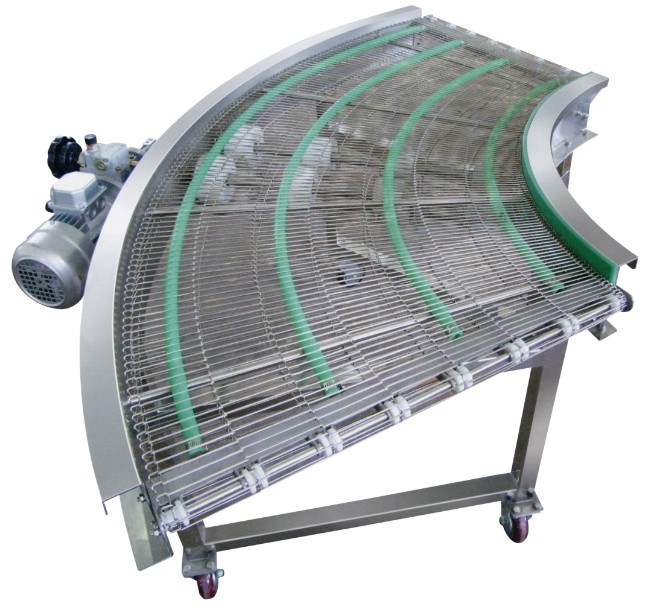

The metal mesh belt conveyor is a material handling machine that continuously transports materials on a certain line, also called a continuous conveyor, and can be divided into a metal mesh belt type and a metal mesh chain type. Conveyors can be horizontal, inclined, and vertical, or they can be made up of space transmission lines, which are generally fixed. The conveyor has a large conveying capacity and a long distance. It can also complete several process operations at the same time during the conveying process. The mesh belt conveyors are made of carbon steel, 201 stainless steel and 304 stainless steel.

structure type

Horizontal straight-line transportation, lifting and climbing transportation and other forms, the conveyor belt can be added lifting baffle, side baffle.

Metal mesh belts are used as delivery carriers.

Driving method

Geared motor drive.

Speed mode

Frequency control, variable speed.

Transportation machinery frame material

Stainless steel, carbon steel.

Range of use

Applicable to all industries such as drying, dehumidification, cleaning, quick freezing and other processes.

1, working principle

The conveyor chain is a sleeve roller chain, continuous bucket structure, used for high temperature clinker level, climbing.

2, the main features

◆ Large conveying capacity: The maximum conveying capacity can reach 526m3/h, and the maximum inclination angle can reach 60 degrees. High temperature resistant, capable of conveying materials with a temperature of less than 600 degrees.

◆ The conveyor chain consists of a traction chain, a load-bearing chain, and a forward lap (or reverse lap) hopper. The three parts can be freely loaded and unloaded.

◆ Rolling bearings are used in load-bearing rollers. Rolling friction is used instead of the conventional sliding friction. The running resistance is reduced by 55% to 65%, which greatly reduces the power consumption of the conveyor and has low energy consumption.

◆ The traction chain and load-bearing chain are separated, simplifying the structure, reducing the cost, and facilitating the installation and maintenance.

◆ Long service life: The traction chain uses long pitch, sleeve roller chain, and the parts of the chain are all made of alloy steel materials; after heat treatment, they are wear-resistant. The weight of the conveying part and the material is borne by the load-bearing parts; the chain no longer bears weight and reduces wear.

◆ The layout of the craft is various: It can be horizontal and inclined, and it can also be arranged by multiple stages of horizontal and inclined combination.

3, applicable areas

◆ Widely used in cement, paper, sugar, chemical and other industries. The most suitable for the material slurry type, granular and so on.